You step inside on a sweltering day and feel that first wave of cool air, it’s instant relief. But have you ever wondered what part of your air conditioner is responsible for making that happen? While thermostats and vents get most of the attention, the real workhorse sits outside, quietly doing its job. It’s called the condenser, and it’s essential to every central cooling system.

What Is a Condenser in an Air Conditioning System?

A condenser is the outdoor component of an air conditioning system that releases heat from inside your home to the outside air. It converts high-pressure refrigerant gas into a liquid, allowing the cooling cycle to continue efficiently.

Key Components of a Condenser

At the heart of the condenser unit are several key components working in unison to complete the refrigeration cycle and maintain indoor comfort. The main parts include the condenser coil, fan, compressor, fins, and refrigerant lines, each one playing a vital role in transferring heat from inside the building to the outside.

The condenser coil is typically made from copper tubing surrounded by aluminum fins, which increase surface area for faster heat dissipation. As the high-pressure refrigerant gas exits the compressor, it flows through this coil, where the fan pulls in outside air to cool it down. This process causes the refrigerant to condense into a liquid, releasing stored heat into the surrounding air. The compressor itself, often considered the “engine” of the system, pumps the refrigerant through the cycle and maintains the high pressure needed for phase changes.

Many units also feature protective grills, control boards, and safety switches, but the coil-fan-compressor trio forms the operational core.

I still remember the first time I cleaned a condenser coil on an older unit at a friend’s rental property. It was mid-summer, and the air conditioner had stopped working altogether. The coil was caked in dust, and lawn debris completely choked off. After carefully cleaning the fins and rinsing the coil with water, we restarted the unit. Within minutes, cool air was flowing again. That moment solidified just how crucial even the smallest components are to an AC system’s performance.

How the Condenser Works in the Cooling Cycle

The condenser is responsible for the critical phase, where heat is expelled from the system. To understand how it works, it’s helpful to look at the larger refrigeration cycle, which follows four main steps: compression, condensation, expansion, and evaporation.

Once the compressor elevates the pressure and temperature of the refrigerant, it enters the condenser coil as a superheated gas. As the outdoor condenser fan blows air over the coils, the refrigerant begins to cool and condense, turning from a gas into a high-pressure liquid. During this phase change, the system releases heat to the outside environment, a process that must occur efficiently for the AC to function well.

The now-liquid refrigerant flows through the expansion valve, where its pressure drops, and then moves into the evaporator coil indoors. There, it absorbs heat from indoor air and evaporates back into a gas, repeating the cycle.

Without the condenser’s ability to reject heat, the system would stall completely. Its performance directly affects how cool, fast, and efficient your AC operates.

Types of Condensers: Air-Cooled vs. Water-Cooled

Condensers come in several types, each tailored to specific system needs, environments, and efficiency goals. The two most common categories are air-cooled and water-cooled condensers.

An air-cooled condenser is the most familiar type and is typically found in residential and light commercial HVAC systems. These units rely on ambient air pulled across the condenser coil by a fan to remove heat from the refrigerant. They are compact, easier to install, and require minimal maintenance since they don’t rely on plumbing or water supply infrastructure.

In contrast, water-cooled condensers use circulating water to extract heat from the refrigerant. The heat is then transferred to a cooling tower or discharged directly, depending on the system. These are more common in large-scale commercial buildings, industrial setups, and environments where ambient air temperatures are too high for effective air cooling. Though more efficient in heat transfer, water-cooled systems are costlier to install and require water treatment and regular maintenance to prevent scale buildup and corrosion.

Additionally, there are evaporative condensers, which combine air and water cooling, and microchannel condensers, which use flat tubes and thin fins to increase heat transfer in compact spaces. Specialized designs like shell-and-tube and finned-tube condensers are also used in industrial or high-load applications.

The choice between these systems depends on factors like climate, energy goals, building design, and long-term operational costs.

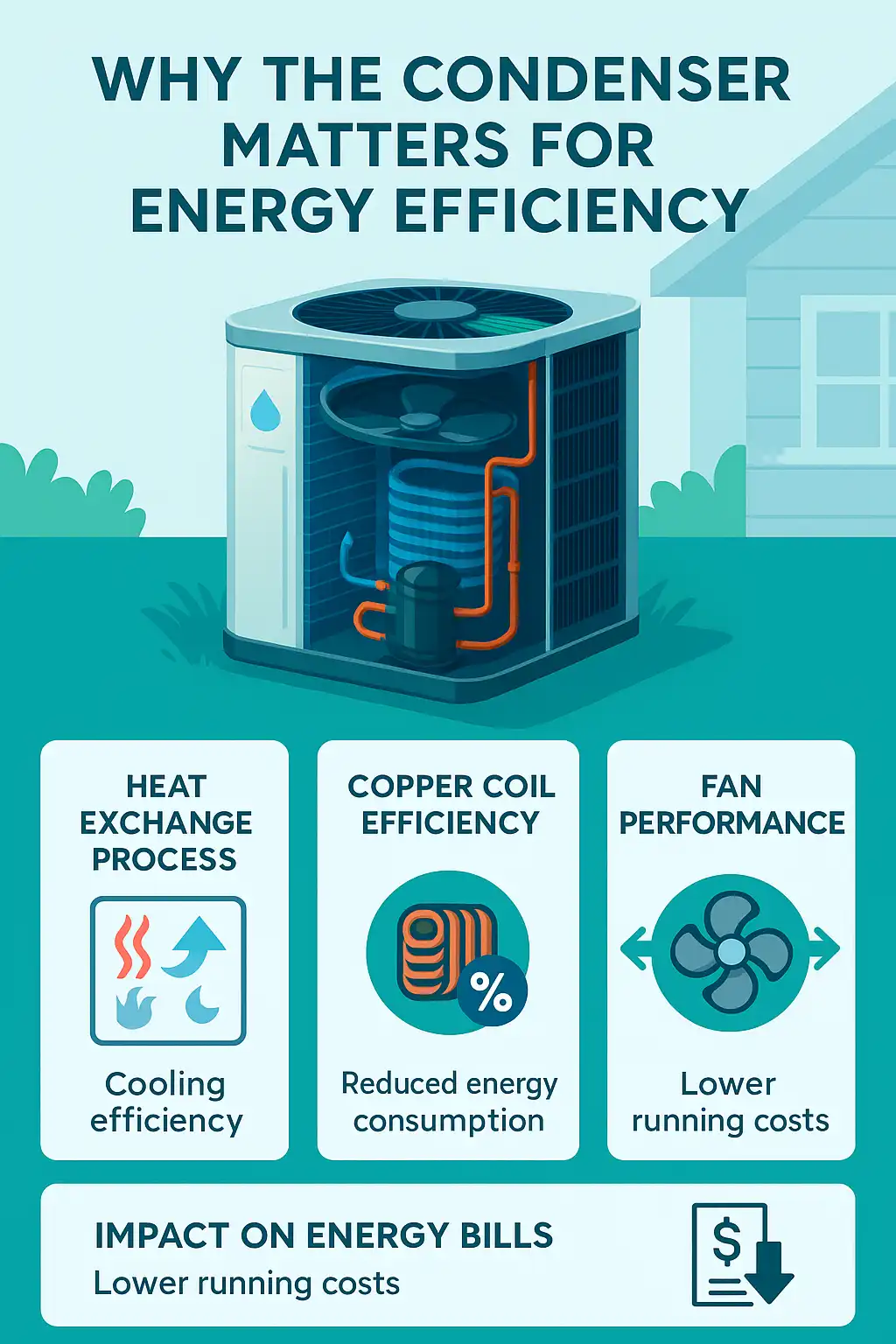

Why the Condenser Matters for Energy Efficiency

The condenser isn’t just a heat-rejecting box outside your building—it plays a direct role in how efficiently your air conditioning system performs. When a condenser operates at peak conditions, it allows the refrigerant to release heat quickly and return to the evaporator coil at the right temperature and pressure. This reduces the overall load on the compressor, which is one of the most energy-intensive components of any HVAC system. As of January 2023, the Department of Energy updated its minimum EER2 and SEER2 standards, making higher-efficiency condensers even more impactful on overall system performance.

A clean, well-functioning condenser coil improves heat exchange and minimizes system strain, translating to lower electricity consumption and longer equipment life. Systems with modern high-efficiency condensers, such as microchannel coils or variable-speed condenser fans, are often rated with higher SEER (Seasonal Energy Efficiency Ratio) values, an essential benchmark for cooling efficiency.

On the flip side, a dirty or damaged condenser coil can trap heat, force the compressor to work harder, and lead to higher utility bills. Even a slight layer of dust or debris on the coil’s surface can reduce its ability to release heat effectively.

Maintaining an efficient condenser isn’t just about keeping your home cool—it’s a key strategy for energy conservation, system durability, and long-term cost savings.

Common Condenser Issues and What to Watch For

Despite being built for outdoor durability, the condenser unit is vulnerable to several issues that can reduce efficiency or lead to system failure.

Watch for these common problems:

-

Coil contamination

-

Dirt, grass, and pollen can insulate the coil

-

Traps heat and forces the compressor to overwork

-

May lead to overheating and automatic shutdown

-

-

Fan motor failure

-

Fan not spinning = no air movement over coils

-

Reduces refrigerant cooling → higher compressor load

-

Clues: unusual noise, vibration, or fan not starting

-

-

Refrigerant leaks

-

Breaks the cooling cycle and disrupts pressure balance

-

May cause reduced cooling or hissing near coils/lines

-

-

Corrosion and electrical faults

-

Rusted coil fins can reduce airflow

-

Wiring issues may cause intermittent failures or shorts

-

-

Clogged drainage

-

Water pooling around the base can damage components

-

Promotes mold, rust, and insects around the unit

-

Pro Tip:

Regular visual inspections help catch small issues before they turn into expensive repairs—especially before peak summer use.

When to Call a Pro for Condenser Maintenance

While basic upkeep like gently rinsing off the condenser coil or clearing debris from around the unit—is safe for most homeowners, certain issues should be left to HVAC professionals. If your system is short-cycling, struggling to cool effectively, or making unfamiliar noises, it’s time to call in a licensed technician.

Routine seasonal maintenance is one of the best ways to keep the condenser in top condition. A professional technician can inspect the refrigerant charge, test capacitors and relays, clean the coil fins with appropriate chemicals, and verify airflow through the fan motor and blades. They’ll also ensure that the electrical connections and safety switches are intact crucial for preventing shorts and component damage.

More advanced concerns, such as refrigerant leaks, compressor testing, or condenser fan replacement, require tools and expertise that go beyond typical DIY fixes. Improper handling of refrigerant not only violates EPA regulations but can also compromise your entire HVAC system.

For best results, schedule a full HVAC inspection at least once a year ideally before the cooling season begins. This helps extend the lifespan of your condenser and improves system reliability when you need it most.

Final Thoughts

The condenser may sit quietly outside your home, but its role in the air conditioning process is anything but passive. It’s the key component responsible for expelling heat, managing refrigerant flow, and ensuring your system delivers consistent, efficient cooling.

Understanding how the condenser works and what can go wrong—gives you an edge in maintaining comfort and controlling energy costs. Whether you’re troubleshooting performance issues or planning seasonal maintenance, the more you know about your condenser, the better your entire HVAC system will run.

If you’re serious about system longevity and efficiency, don’t overlook the unit outside. That’s where the real heat exchange happens and where smart maintenance begins.

Need Professional AC Service or Condenser Repair?

If you’re experiencing cooling issues or just want to make sure your system is running at peak efficiency, our HVAC experts are here to help. Whether it’s a routine inspection or emergency condenser repair, we offer fast, professional service you can trust. Schedule your appointment today with Richmond Air and keep your system running cool all season long.

FAQs: Condensers in Air Conditioning Systems

Q: What does the condenser do in an AC system?

A: The condenser releases the heat absorbed from indoor air to the outside environment by converting high-pressure refrigerant gas into a liquid.

Q: Is the condenser the same as the compressor?

A: No. The compressor pressurizes the refrigerant, while the condenser removes heat from it. They are separate but closely connected components.

Q: Where is the condenser located?

A: In most residential systems, the condenser is housed in the outdoor unit, typically alongside the compressor and fan.

Q: Can a dirty condenser coil affect cooling performance?

A: Absolutely. A dirty coil reduces heat transfer, forcing the compressor to work harder and increasing energy consumption.

Q: How often should I clean or check the condenser unit?

A: Inspect the unit every few months, especially during heavy-use seasons. Schedule professional maintenance at least once a year.

Q: What are the signs of condenser failure?

A: Poor cooling, unusual noises, fan not spinning, and high electricity bills can all point to condenser problems.

Q: Can I replace just the condenser unit?

A: Technically, yes, but it’s often best to upgrade both indoor and outdoor units together for optimal compatibility and efficiency.